Buying a Home? Here’s How You Can Determine Its Construction

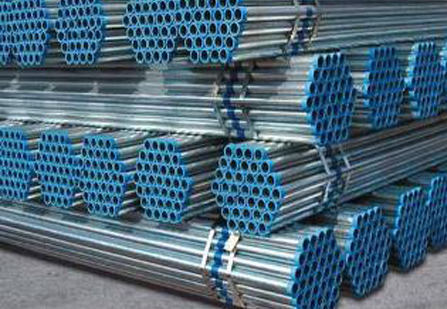

Scaffolding stands as a cornerstone in the construction industry, providing crucial support for tasks conducted at elevated heights. Among the array of scaffolding options available, GI (Galvanized Iron) pipe scaffolding has gained prominence owing to its numerous advantages over its counterparts. Let's delve into these key benefits that make GI pipe scaffolding a preferred choice in construction projects.

• Protection Against Corrosion and Rust

GI pipe scaffolding, crafted from galvanized iron, comes equipped with a layer of zinc coating. This protective shield is a formidable defence against corrosion and rust, ensuring the structural integrity of each pipe. Particularly in environments with high humidity or coastal areas prone to rust issues, utilizing GI pipe scaffolding becomes paramount for worker safety. Unlike wooden scaffolding, which may succumb to damage from moisture, pests, and sun exposure, therefore GI pipe scaffolding offers enhanced durability and minimizes risks associated with rust-related hazards.

• Support for Heavy Loads and Extreme Pressure

The exceptional strength of GI pipe scaffolding makes it a reliable asset for diverse construction projects. These scaffolding can support heavy loads and withstand extreme pressure, ensuring unparalleled stability and durability. This strength sets it apart from alternatives like bamboo scaffolding, making it ideal for high-rise projects or any undertaking requiring scaffolding with robust load-bearing capacity.

• Easy Assembly and Disassembly

In contrast to scaffolding types requiring specialized tools and expertise, GI pipe scaffolding stands out for its ease of assembly and disassembly. Basic tools suffice for these tasks, reducing labour hours and making it a cost-effective option. Quick setup enables construction projects to commence promptly, contributing to efficient project timelines. The flexibility of GI pipe scaffolding, available in various lengths and diameters, further enhances its adaptability to diverse project requirements.

• Ease of Transport

The lightweight nature of GI pipes facilitates easy transportation to construction sites, even in remote locations. This attribute streamlines material and equipment transport, enhancing overall construction efficiency. Quick and straightforward installation at sites accelerates project timelines, making GI pipe scaffolding a preferred choice, especially for projects in remote locations where transportation challenges are common.

• Slip resistance for Enhanced Safety

Prioritizing worker safety is paramount in construction, and GI pipe scaffolding provides a secure working environment. The zinc layer on GI pipes makes them less slippery, which helps prevent falls and injuries, especially in outdoor construction sites when it's wet. The durability and strength of GI pipe scaffolding offer workers peace of mind while performing tasks at elevated heights.

• Reusability for Sustainability

GI pipe scaffolding stands out as a sustainable option, capable of being reused in multiple projects. Following project completion, the scaffolding can be disassembled and inspected, and any damaged components replaced. This reusability proves cost-effective and reduces waste, aligning with sustainability goals in the construction industry.

In Sri Lanka, Melwa GI Pipes is well-known for scaffolding in construction projects, offering assured and strong quality.

Melwa Foundation #unity #diversity #priceless

GI pipe scaffolding, crafted from galvanized iron, comes equipped with a layer of zinc coating. This protective shield is a formidable defence against corrosion and rust, ensuring the structural integrity of each pipe. Particularly in environments with high humidity or coastal areas prone to rust issues, utilizing GI pipe scaffolding becomes paramount for worker safety. Unlike wooden scaffolding, which may succumb to damage from moisture, pests, and sun exposure, therefore GI pipe scaffolding offers enhanced durability and minimizes risks associated with rust-related hazards.

• Support for Heavy Loads and Extreme Pressure

The exceptional strength of GI pipe scaffolding makes it a reliable asset for diverse construction projects. These scaffolding can support heavy loads and withstand extreme pressure, ensuring unparalleled stability and durability. This strength sets it apart from alternatives like bamboo scaffolding, making it ideal for high-rise projects or any undertaking requiring scaffolding with robust load-bearing capacity.

• Easy Assembly and Disassembly

In contrast to scaffolding types requiring specialized tools and expertise, GI pipe scaffolding stands out for its ease of assembly and disassembly. Basic tools suffice for these tasks, reducing labour hours and making it a cost-effective option. Quick setup enables construction projects to commence promptly, contributing to efficient project timelines. The flexibility of GI pipe scaffolding, available in various lengths and diameters, further enhances its adaptability to diverse project requirements.

• Ease of Transport

The lightweight nature of GI pipes facilitates easy transportation to construction sites, even in remote locations. This attribute streamlines material and equipment transport, enhancing overall construction efficiency. Quick and straightforward installation at sites accelerates project timelines, making GI pipe scaffolding a preferred choice, especially for projects in remote locations where transportation challenges are common.

• Slip resistance for Enhanced Safety

Prioritizing worker safety is paramount in construction, and GI pipe scaffolding provides a secure working environment. The zinc layer on GI pipes makes them less slippery, which helps prevent falls and injuries, especially in outdoor construction sites when it's wet. The durability and strength of GI pipe scaffolding offer workers peace of mind while performing tasks at elevated heights.

• Reusability for Sustainability

GI pipe scaffolding stands out as a sustainable option, capable of being reused in multiple projects. Following project completion, the scaffolding can be disassembled and inspected, and any damaged components replaced. This reusability proves cost-effective and reduces waste, aligning with sustainability goals in the construction industry.

Melwa Foundation #unity #diversity #priceless

Have Any Question?

Contact our team

- (+94) 71 26 30 298

- support@Melwa.com